Forged Heat Sinks for electronic systems

Hirschvogel has been a strong and valued partner to the automotive industry for decades in the field of forged components made of steel and aluminum.

The transformation to electromobility poses challenges for suppliers and demands a high degree of flexibility. At the same time, it also holds a wealth of opportunities, as Hirschvogel has already impressively demonstrated by taking over the market leadership for rotor shafts.

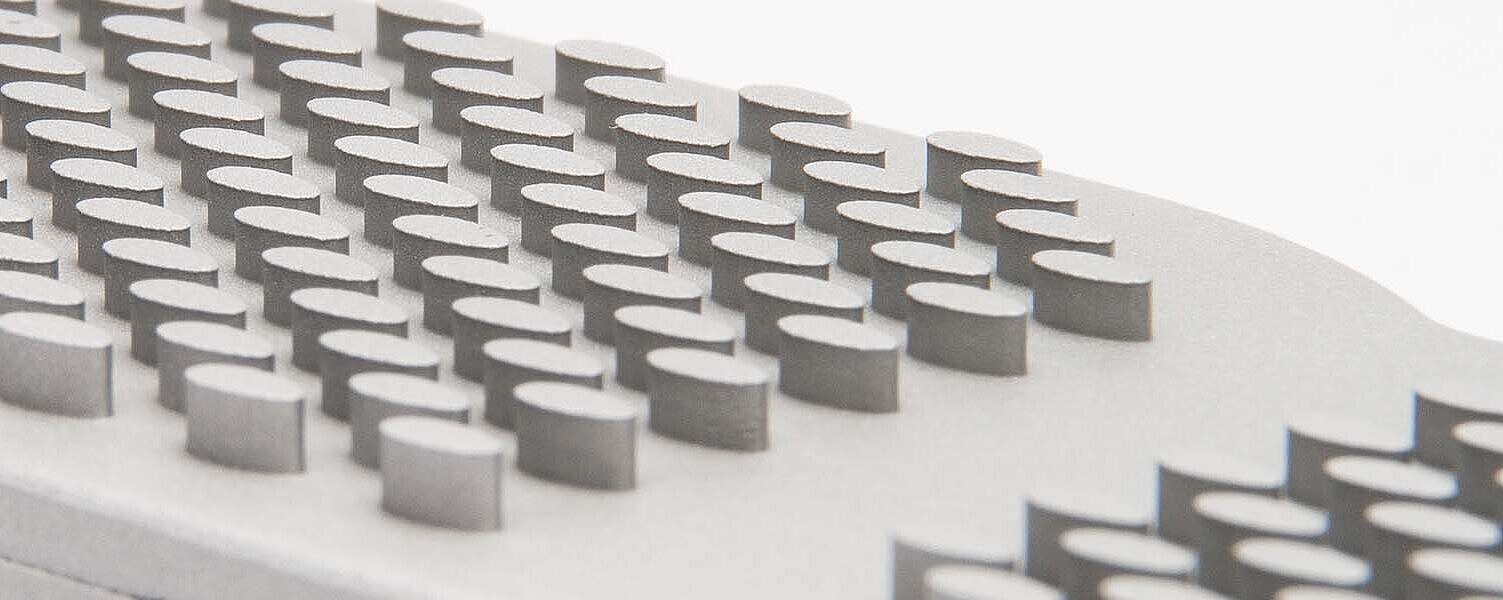

Many systems contain forgings that are not recognizable as such at first glance, including in the area of electronic systems. Here, cooling elements are required for heat dissipation. These systems can benefit from the good properties of forged components. Hirschvogel is therefore striving for a leading position when it comes to heat sinks, too, and is expanding its product range to include complex cooling plates made of copper or aluminum.

Broad production spectrum for heat sinks

The range includes both cold and hot forged heat sinks. By means of cold forging, precise dimensions, thin wall thicknesses, and an increase in strength are possible. Hot forging is better suited to geometrically complex structures. In this way, Hirschvogel can fulfil individual requirements specific to each customer and benefit from its longstanding expertise in the production of forged components.

The existing machines enable the production of cooling plates with large dimensions. If the customer wishes to purchase a ready-for-assembly component, a wide range of further processing options are available. These include machining as well as any necessary deburring processes, or else final cleaning and coating.

The material makes the difference

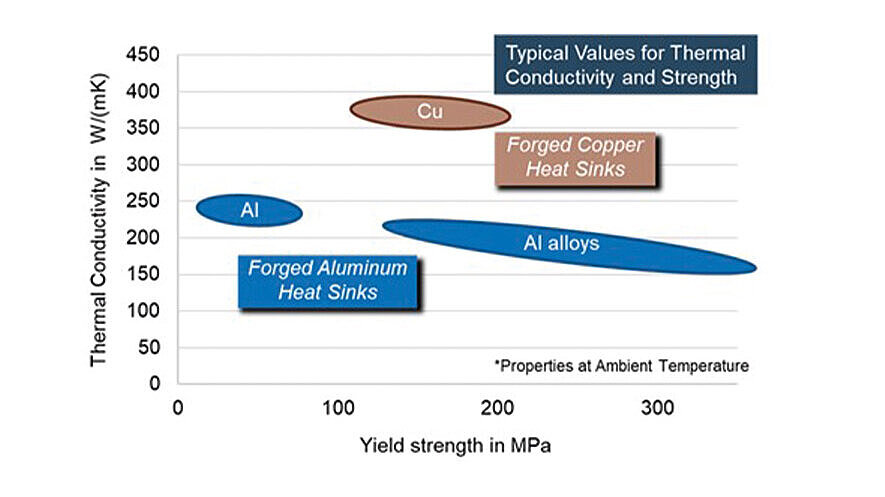

Very high thermal conductivity combined with very good mechanical properties characterize forged heat sink components made of wrought aluminum alloys. Copper represents a potential solution for increased cooling performance requirements. Here, the thermal conductivity is almost twice as high as that of aluminum, thereby achieving a significantly higher cooling performance in the same assembly space.

Forged heat sinks enable improved heat dissipation, which in turn results in higher power density as well as increased service life for electronic components. Furthermore, the components are pressure-tight, cavity-free, and easy to weld. In addition to improved product properties, these advantages also lead to cost savings in the assembly of cooling systems.

Everything from a single point of contact

Hirschvogel supplies ready-for-assembly components that include further processing. Many of our customers appreciate having a single point of contact for all their requirements.

Have we sparked your interest, and would you like to know more? Please get in touch with us. We would be happy to advise you and look forward to speaking with you.