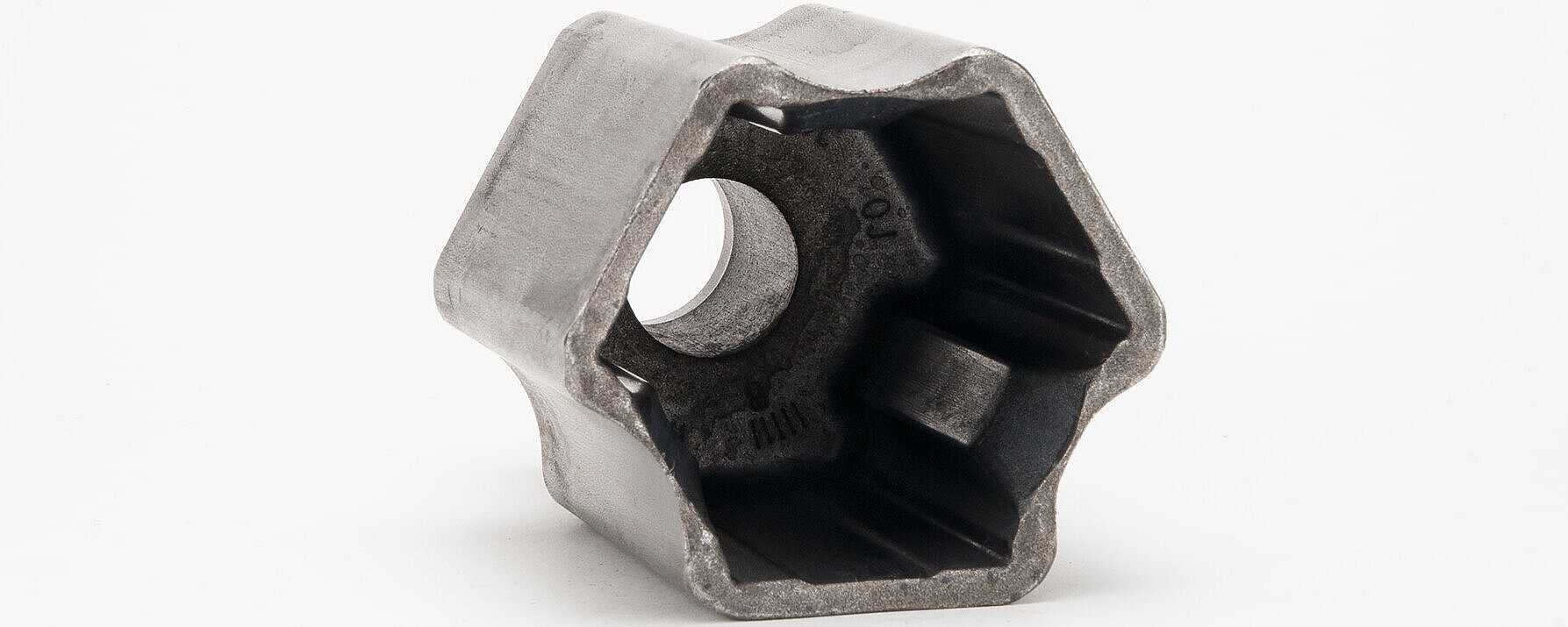

Triopod

Tripods are used in constant-velocity shafts. They have an axial displacement function which enables length compensation of the side shaft. These parts are produced through a combination of warm and cold forging. Depending on the interface, the shaft area can already be punched during the forging process. Following cold forging, the internal surface is then ready for induction hardening.