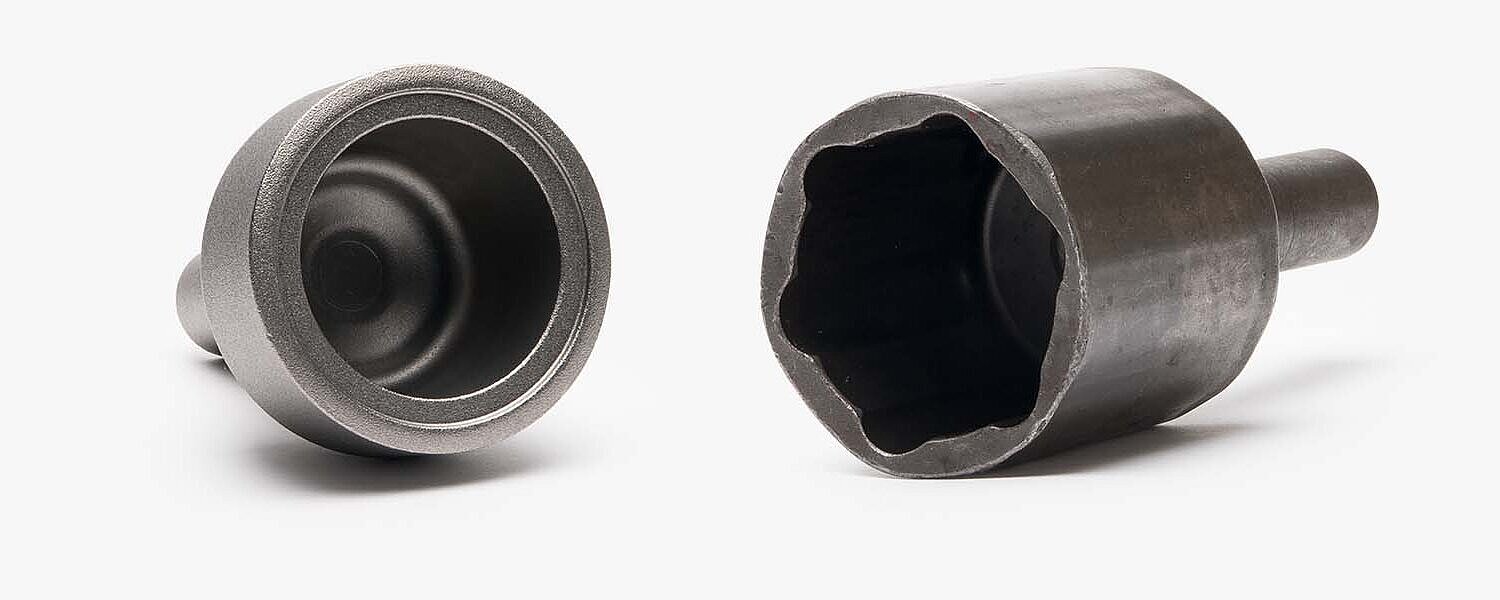

Plunge Ball Joint

Plunge ball joints are used in constant-velocity shafts. They have an axial displacement function which enables length compensation of the side shaft. There are two main designs: the cross-groove joints and the double-offset (DO) joints. Hirschvogel produces these joints worldwide for a number of renowned system and automotive manufacturers. When applied on the wheel side, Hirth teeth can also be used. These offer advantages in terms of production costs and system weight.