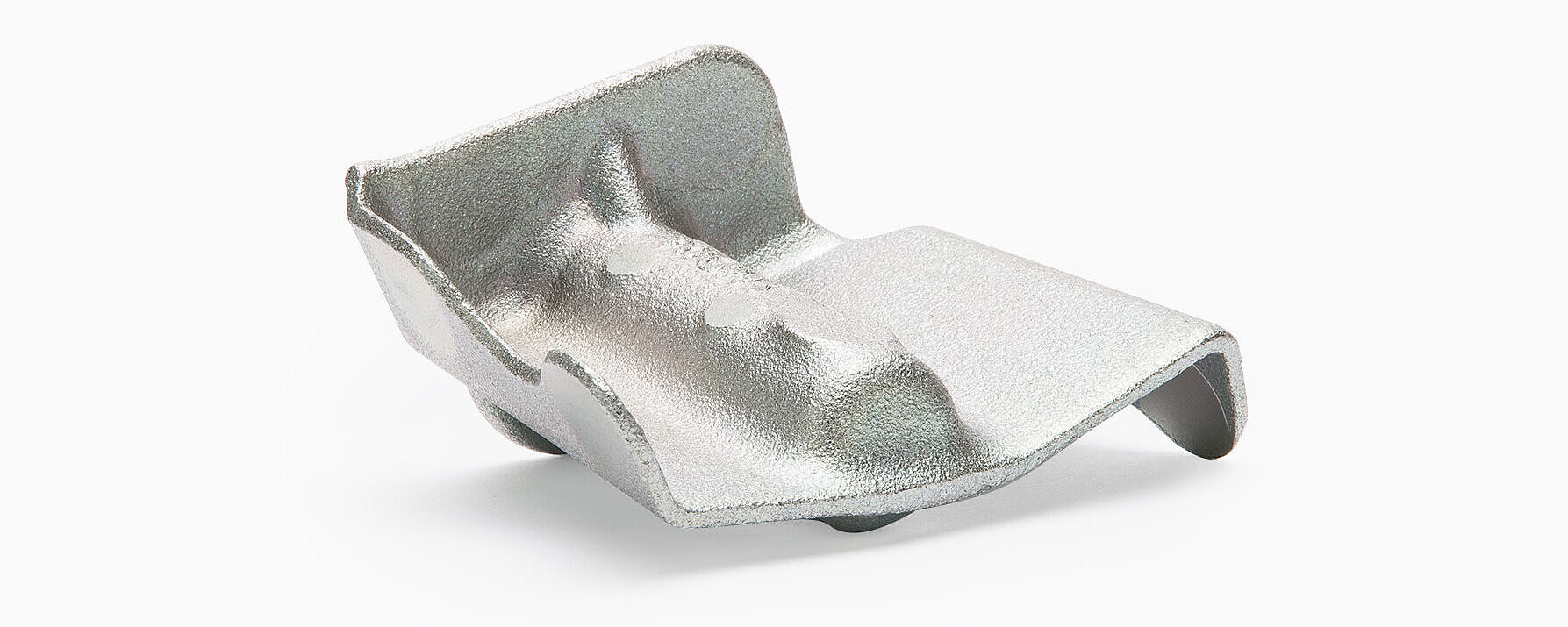

Connecting Component

Forgings are ideally suited for generating bolt-on points on the vehicle body, for example to accommodate subframes. The monoblock design results in very good properties in terms of fatigue strength and energy absorption in the event of a crash. During the calibration process, the wall thickness is also partially reduced to such an extent that the component can be joined cost-efficiently to the remaining sheet metal parts of the body by means of spot welding.