Premium Cooling – Flex Cooling Power Module

Basic Concept

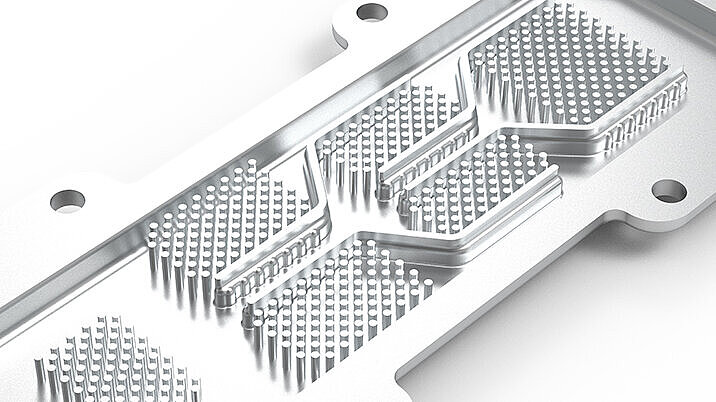

The Flex Cooling Power Module is based on an innovative pin-fin heat sink design that was developed specifically for the efficient cooling of power modules in traction inverters. The design comprises a cold forged solution that uses aluminum wrought alloys with high thermal conductivity. The channel structure of the heat sink directs the coolant flow in a targeted manner to achieve maximum cooling performance based on parallel alignment of the coolant flow. This dissipates heat more efficiently and ensures a more even temperature distribution across the power modules.

Engineering

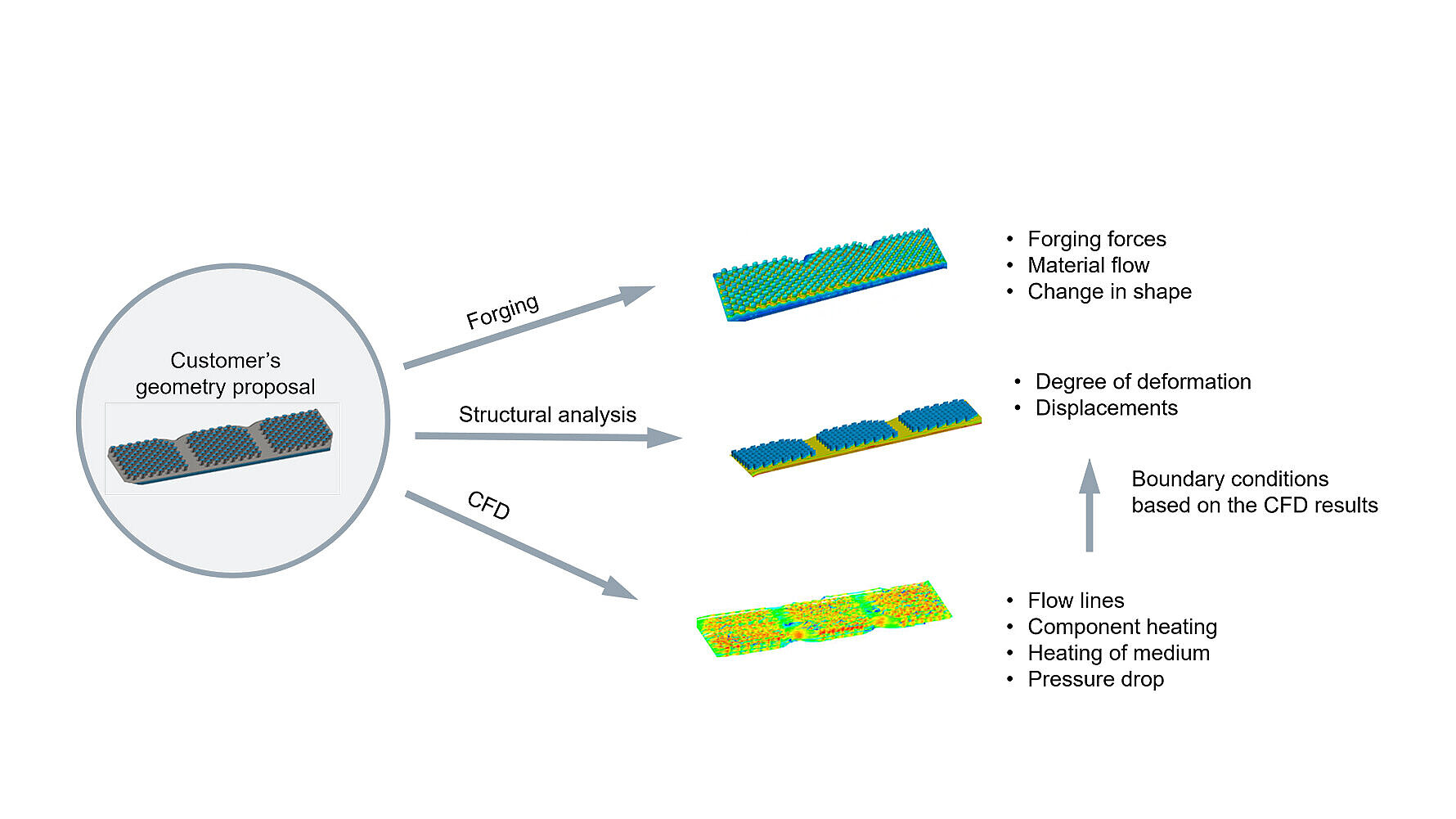

The simulation tools used in development enable the precise design and optimization of the cooling structure and ensure that the thermal and structural requirements of the customers are met. Once the design has been finalized, the manufacturing process for large-series production is designed and implemented. Customers are guaranteed high production quality based on uniform manufacturing standards, regardless of whether the components are produced in Germany or China.

Advantages of the Flex Cooling Power Module

The Flex Cooling Power Module offers decisive advantages over conventional heat sinks with serial coolant flow:

Improved cooling performance: Higher cooling efficiency can be achieved through targeted parallel flow to the specific areas that need to be cooled.

More homogenous cooling: The parallel coolant flow also ensures a more even temperature distribution across the power modules. This increases the efficiency and reliability of the modules by reducing thermal hotspots.

Lower pressure drop: The cooling structure results in a lower pressure drop, improving the efficiency of the coolant flow and reducing the energy consumption of the coolant pump.

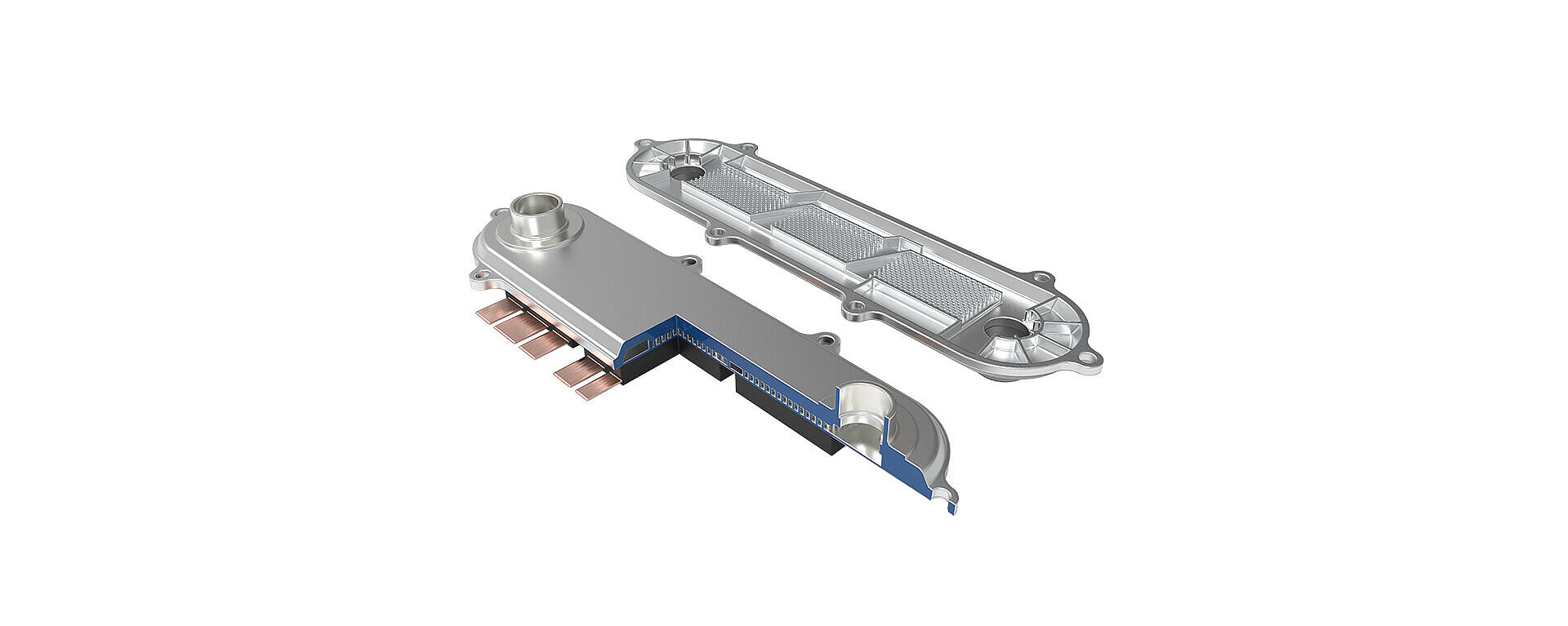

Fig.: Example of an implemented Flex Cooling Power Module

In summary, Hirschvogel’s cooling concept is an innovative thermal management solution for traction inverter power modules in battery-electric vehicles. This concept has already been implemented in customer projects, where it has demonstrated high cooling performance with low pressure loss.

Interested? Then get in touch with us!