Lightweight Design Meets Sustainability

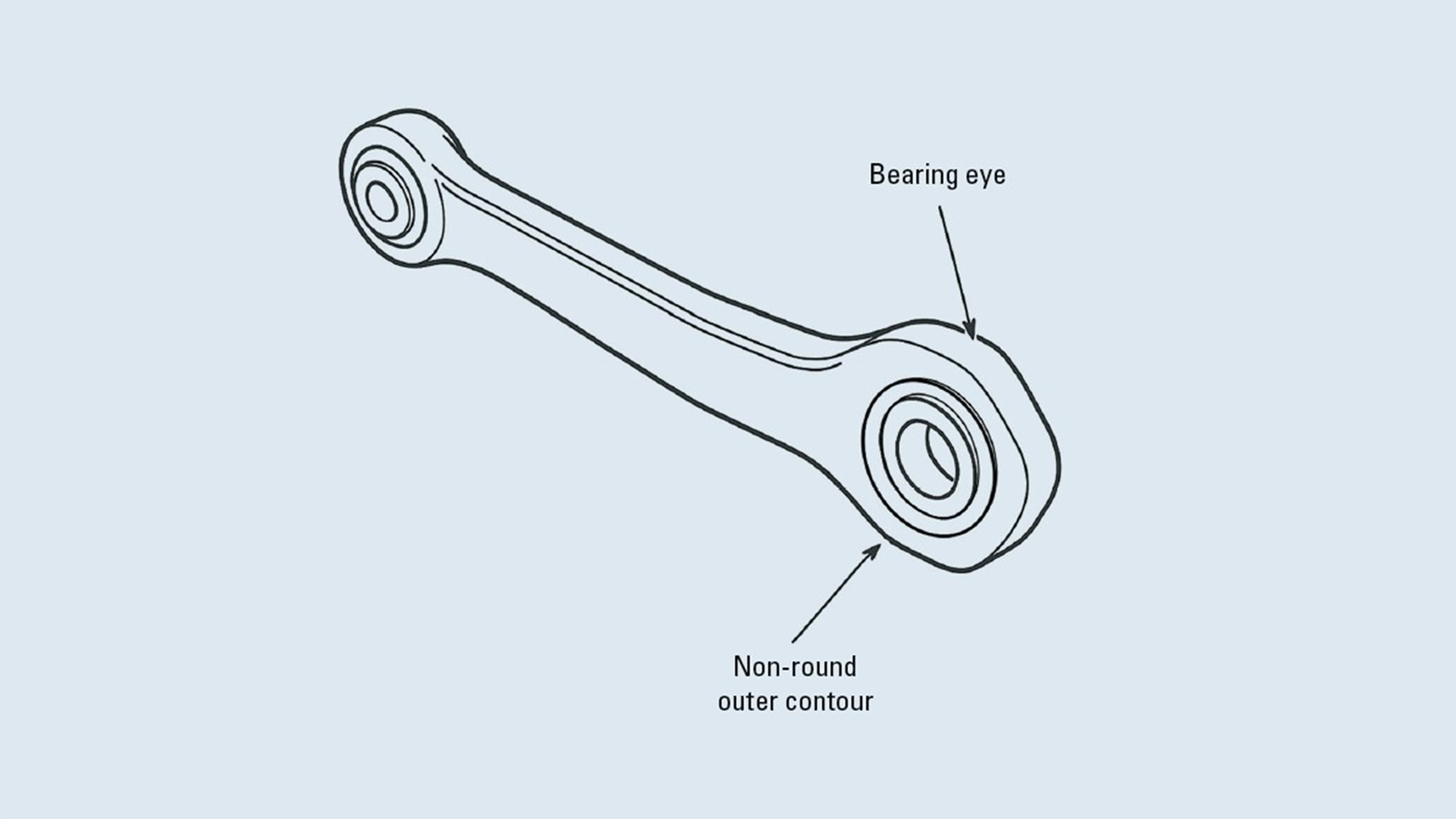

When developing our chassis components, we at Hirschvogel are constantly faced with the challenge of combining technical excellence with resource conservation and sustainability. A current example of this is the optimization of control arm components through a special design idea: bearing eyes with a non-round outer contour.

The many ways in which non-round bearing eyes improve our chassis components

What may sound remarkably simple at first actually holds great potential. Whereas round geometries have been used to date, the new geometry allows us to reduce the amount of material specifically in areas where it is not mechanically necessary. This is made possible by modern simulation and manufacturing technologies – and by the expertise of our Development teams.

More than just a few grams

Even if the weight saving per component only amounts to a few grams, this quickly adds up when large volumes are involved – over the course of a year, several tons of raw material can be saved. This not only means lower costs, but also a tangible reduction in our carbon footprint – a win-win situation for both the environment and the company. Every gram saved also contributes to reducing the total weight of vehicles – and thus to lowering energy consumption and CO₂ emissions during operation. This development is becoming particularly important in the field of electromobility, where range and efficiency are key criteria.

A plus for efficiency and service life

The new geometry also has other advantages too, as it ensures a more even distribution of stress within the component, thereby preventing stress peaks. This increases the service life of the control arm and makes it more robust under dynamic loads – a real step forward in terms of quality and safety.

A strong sign of our innovative strength

Particularly pleasing is the fact that no additional effort is required in Tool- and Diemaking or Production to achieve this new geometry. Integration into our existing processes is running smoothly – a testament to how well Development and Production work hand in hand at Hirschvogel.

The idea was registered as an invention at an early stage and a patent application was filed. After successful examination, patent DE 10 2024 114 742 B3 was granted by the German Patent Office, enabling us to exclusively offer this innovation to our customers.

Fig.: Control arm where the outer contour of the bearing is non-round